Share your experience!

We want to make the drive, head gear and processes better for everyone! If you ordered drives or head gear from us, share your experience and feedback! And if you have helpful tips, alternative protocols, or resources that might benefit the community, get in touch as well!

On this page, you can find links to instructions for how to use the R2Drive, and additional tips related to manufacturing of the first pre-order batch. As this page is thought as a starting point for people who ordered the R2Drive through 3Dneuro, some information might apply differently if you printed the drive yourself or had it made elsewhere.

General Resources

Implantation protocols

Vöröslakos, M., Petersen, P. C., Vöröslakos, B., & Buzsáki, G. (2021). Metal microdrive and head cap system for silicon probe recovery in freely moving rodent. ELife, 10, e65859. https://doi.org/10.7554/eLife.65859

The publication contains a concise implantation protocol for the drive and head gear.

Vandecasteele, M., M., S., Royer, S., Belluscio, M., Berényi, A., Diba, K., Fujisawa, S., Grosmark, A., Mao, D., Mizuseki, K., Patel, J., Stark, E., Sullivan, D., Watson, B., & Buzsáki, G. (2012). Large-scale Recording of Neurons by Movable Silicon Probes in Behaving Rodents. Journal of Visualized Experiments, 61. https://doi.org/10.3791/3568

An extensive, video-based protocol for creating versatile implantations suitable for multi-drive implants.

Citations

If you use the R2Drive, rat cap, or mouse cap, please cite the paper by Vöröslakos et al.:

Metal microdrive and head cap system for silicon probe recovery in freely moving rodent. Mihály Vöröslakos, Peter C. Petersen, Balázs Vöröslakos, György Buzsáki doi: 10.7554/eLife.65859

If you purchased the R2Drive or head gear from 3Dneuro, we would appreciate if you mention us in your methods section (for example, “The silicon probes were mounted on metal microdrives (R2Drive, purchased from 3Dneuro, Nijmegen, The Netherlands)”)

Manufacturing notes and preparation of R2Drives, rat and mouse caps

Below, you will find important notes on drive lubrication, resoldering (if necessary), sealing the drive base, using a pin, and manufacturing information about the drive base-body connection, mouse and rat cap.

Note: Here we link to the Youtube versions of the tutorial videos, as they allow links to specific times. If you prefer staying within the GitHub ecosystem, you can navigate to the same times (check the t= in the link) in the videos on https://buzsakilab.github.io/3d_print_designs/

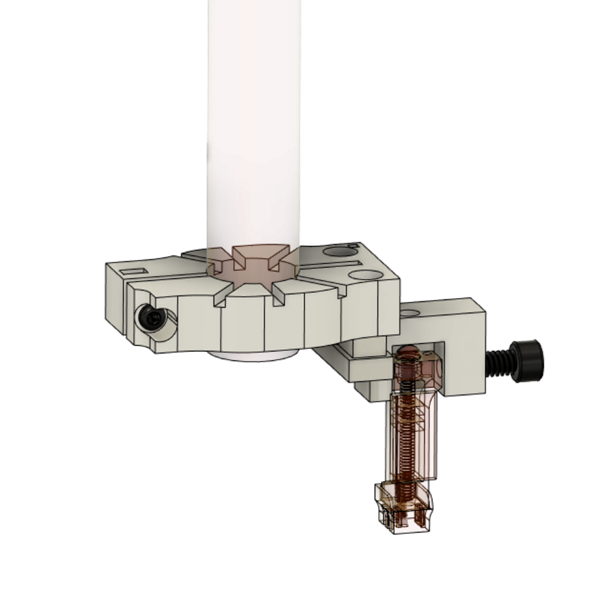

R2Drive lubrication and smooth operation

Any kind of lubrication can deteriorate over time. If you handle the drive in a way that removes the mineral oil (e.g. sterilization in alcohol) or if the movement is not smooth, consider adding a drop of mineral oil on the drive screw and the gap between nut and drive body to restore smooth movement.

R2Drive base sealing

To make sure that no dental cement runs into the base and fixates it to the drive body, the hole on the bottom of the drive base should be closed off. For this purpose, the original protocol recommends sealing the hole with a bit of play-doh and adding a layer of dental cement. We do not perform this step, as the sealant you can or want to use might differ from this protocol.

See https://youtu.be/poEjWvFrr5g?t=115 for a video of the sealing process.

R2Drive: What about the pin?

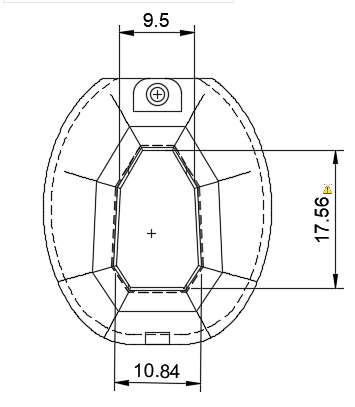

Our R2Drive design contains a round 0.8mm hole on the top, next to the screw head. It can hold a 0.8mm dowel pin, which can be useful in some settings to, for example, hold the Omnetics connectors during specific surgery protocols. The hole on some drives is quite tight – please make sure the pin fits before loading an electrode. If it is too tight, you can loosen it a bit with a 0.8mm (or 1/32 in) drill. As the drive body is made from aluminum, soldering the pin to the body is tricky. Instead, fix it with glue or a small amount of dental cement, which you can remove during surgery by melting it away with a soldering iron or any other hot metal (e.g., tweezers that were heated up in a hot bead sterilizer).

Most users will not need this option. Nonetheless, we include a few fitting pins with your drives. To avoid waste, we add less than one per drive (depending on how many you ordered), as they are only used until the implantation surgery. If you like to have additional pins in later orders, let us know.

Mouse cap

The mouse cap ships ready for assembly. We tapped all the holes and inserted the screws so that they do not get lost during shipping.

You only need to connect the header pins (included in the bag, see https://youtu.be/_MYBLJf-178?t=60) and copper mesh (included in separate bag, see https://youtu.be/_MYBLJf-178?t=180).

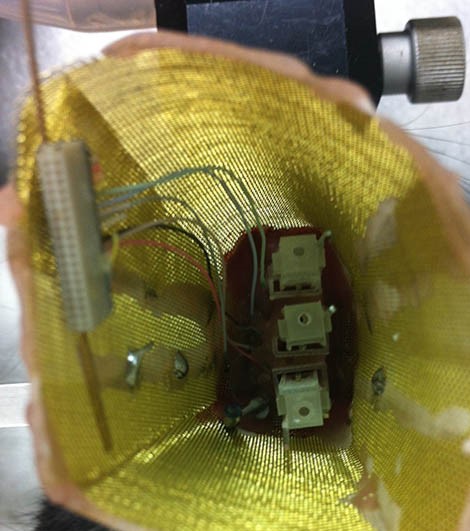

Rat cap

The rat cap also comes ready for assembly. We tapped all the holes and inserted the screws so that they do not get lost during shipping.

We include enough copper tape to cover the inside of the rat caps (see https://youtu.be/SgM9TPhbf_Y?t=113 ). If you use a digital data acquisition system that digitizes the signal on the headstage (like OpenEphys or Neuropixels) in a shielded environment (like a Faraday cage), you can consider skipping that step.

If you need to access your implants on a daily basis (when recording), we recommend not using the 3D printed lid. Close the rat cap with some self-adherent wrap instead (e.g., Coban wrap).